Development

We enjoy to be creative. Our work has resulted in a variety of new approaches as well as patents in several fields of engineering.

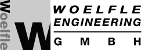

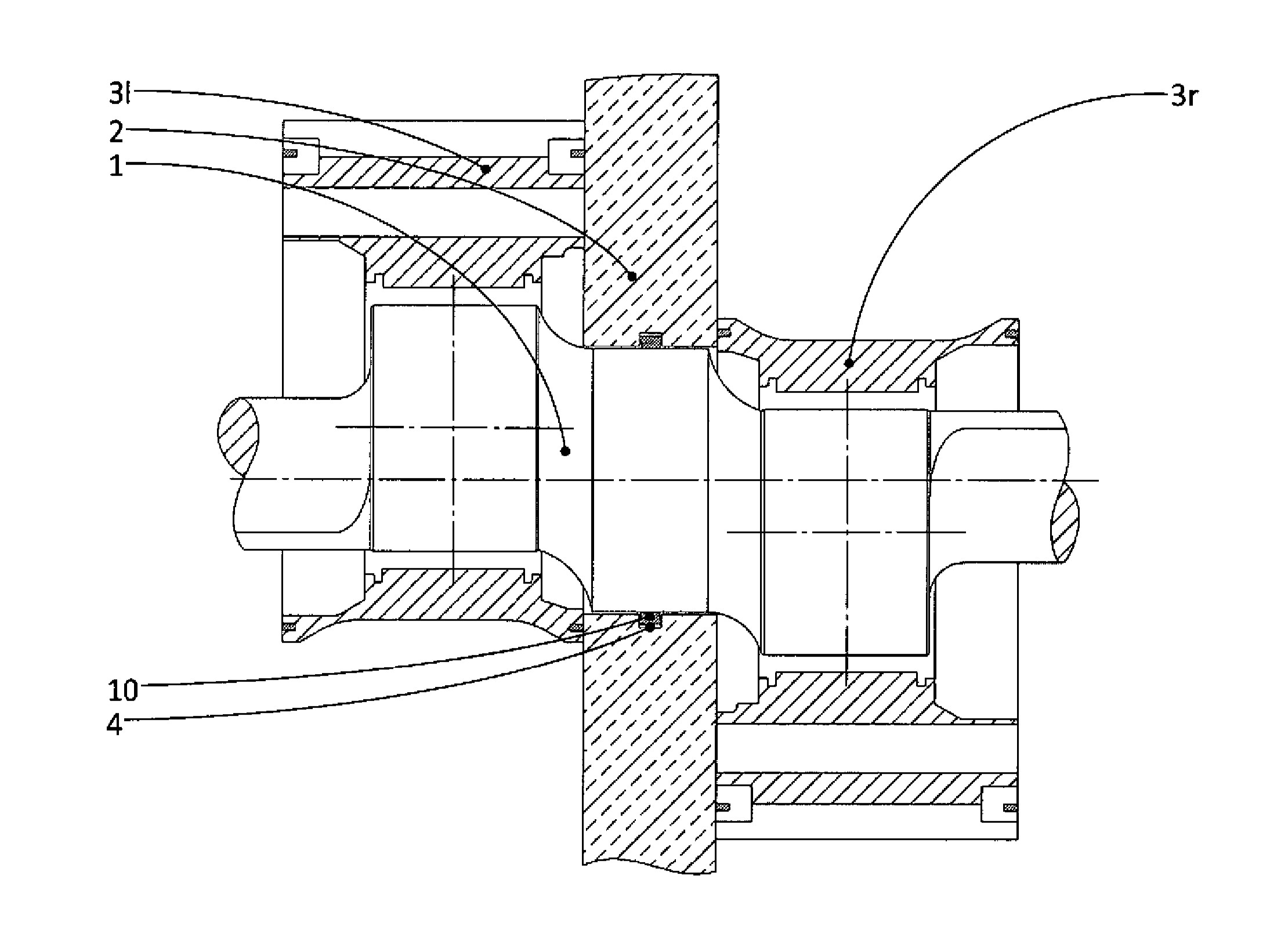

Rotary Engines

The main focus of Woelfle Engineering has been on rotary engines for the last two decades. Besides designing and making engines, we have also developed ideas to improve them. This has resulted in better engines – and a few patent applications.

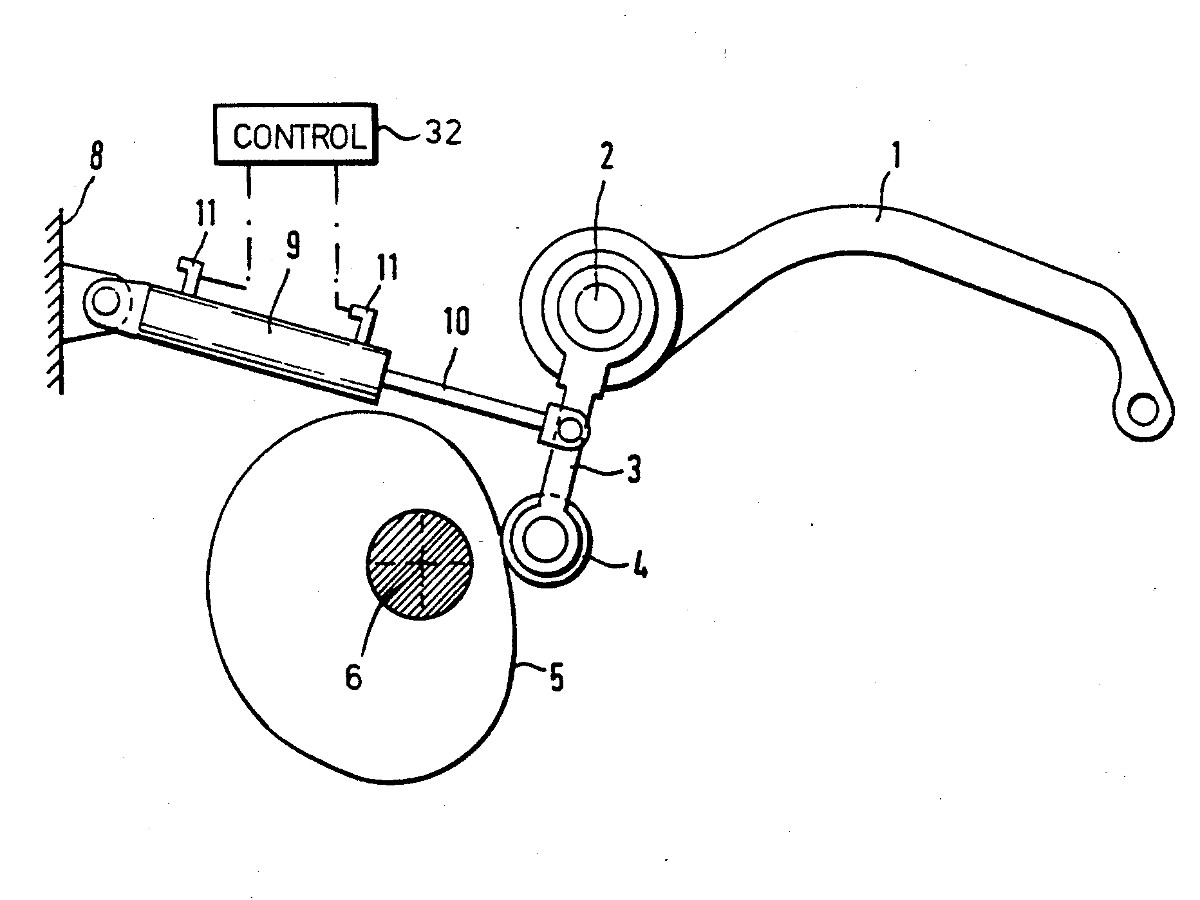

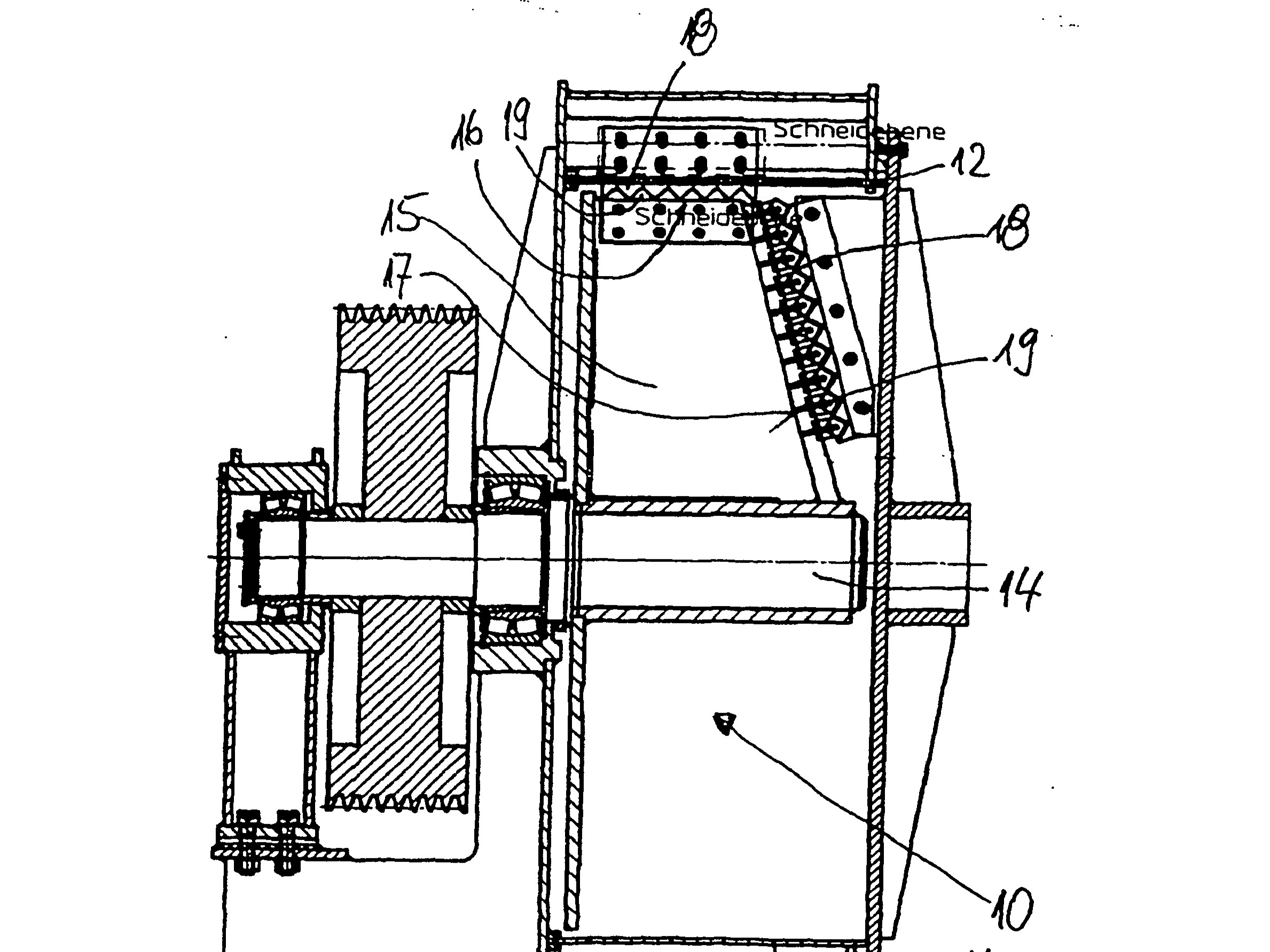

Embroidery Machines

Several improvements have been made in the field of embroidery machines, both in previous industry positions and at Woelfle Engineering. For example an improved thread takeup and a balanced sewing head have been introduced.

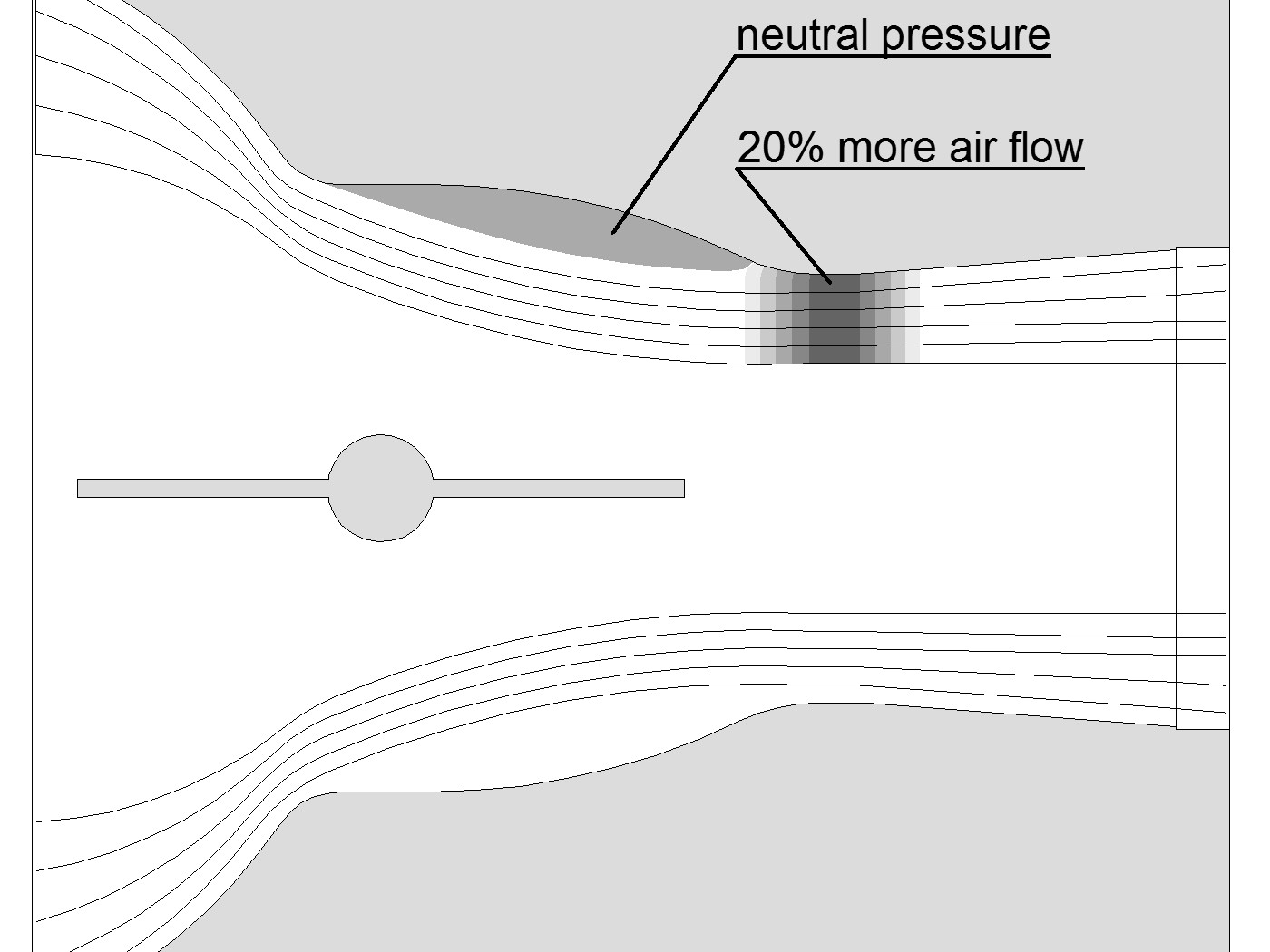

Carburettor for 2-Stroke Kart Racing

Conventional diaphragm carburettors are designed with a butterfly throttle valve on the engine side of the most narrow inlet section (“venturi”). This makes it easier to control fuel flow when the butterfly is closed, but the butterfly and butterfly shaft disturb the air flow in the inlet section. Usually this is compensated by using larger inlet diameters, but in some cases, such as kart racing, this was not possible, because the diameter was limited for regulatory reasons and the use of a butterfly (rather than a slide valve) was mandatory.

Our solution to this was to make a carburettor with a butterfly valve on the inlet side of the venturi in combination with a specific fuel delivery setup that controlled fuel flow when the butterfly was closed. The carburettor was complex, but it was fast and raced by later Formula 1 drivers.

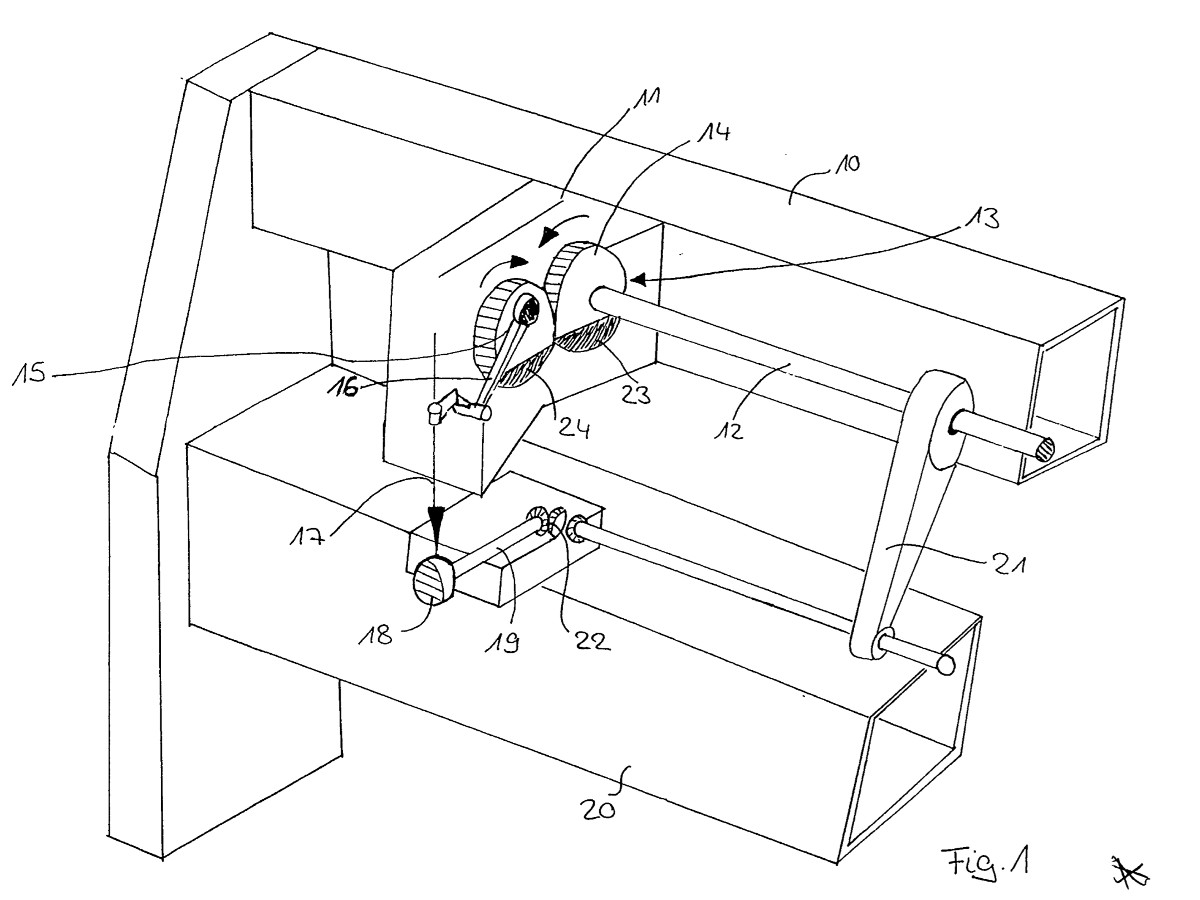

Plastic Shredding

A development project with the task to shred thin-walled plastic elements, such as bottles, resulted in another patent application. Benefits of the design were high durability and performance of the shredding device as well as a good quality of the shredded material, which facilitated subsequent recycling processes.

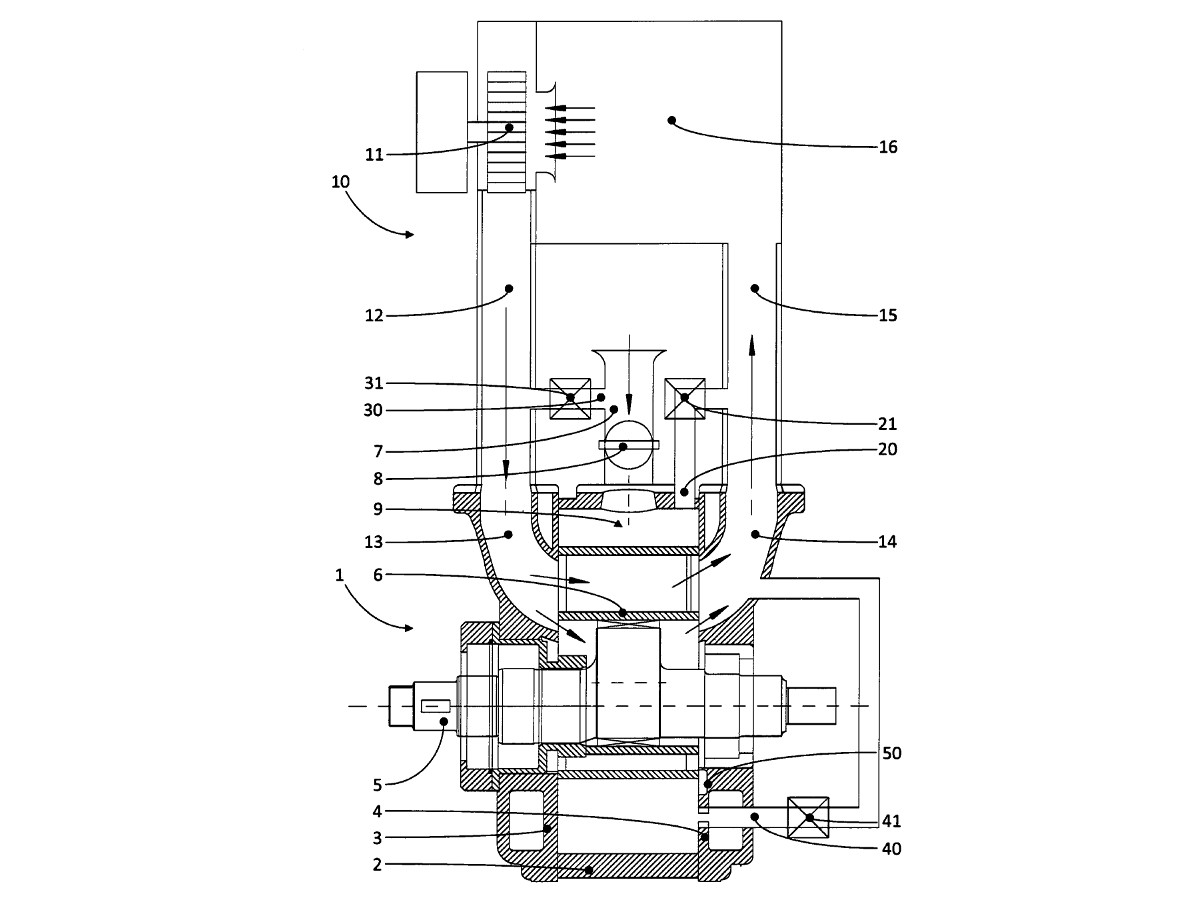

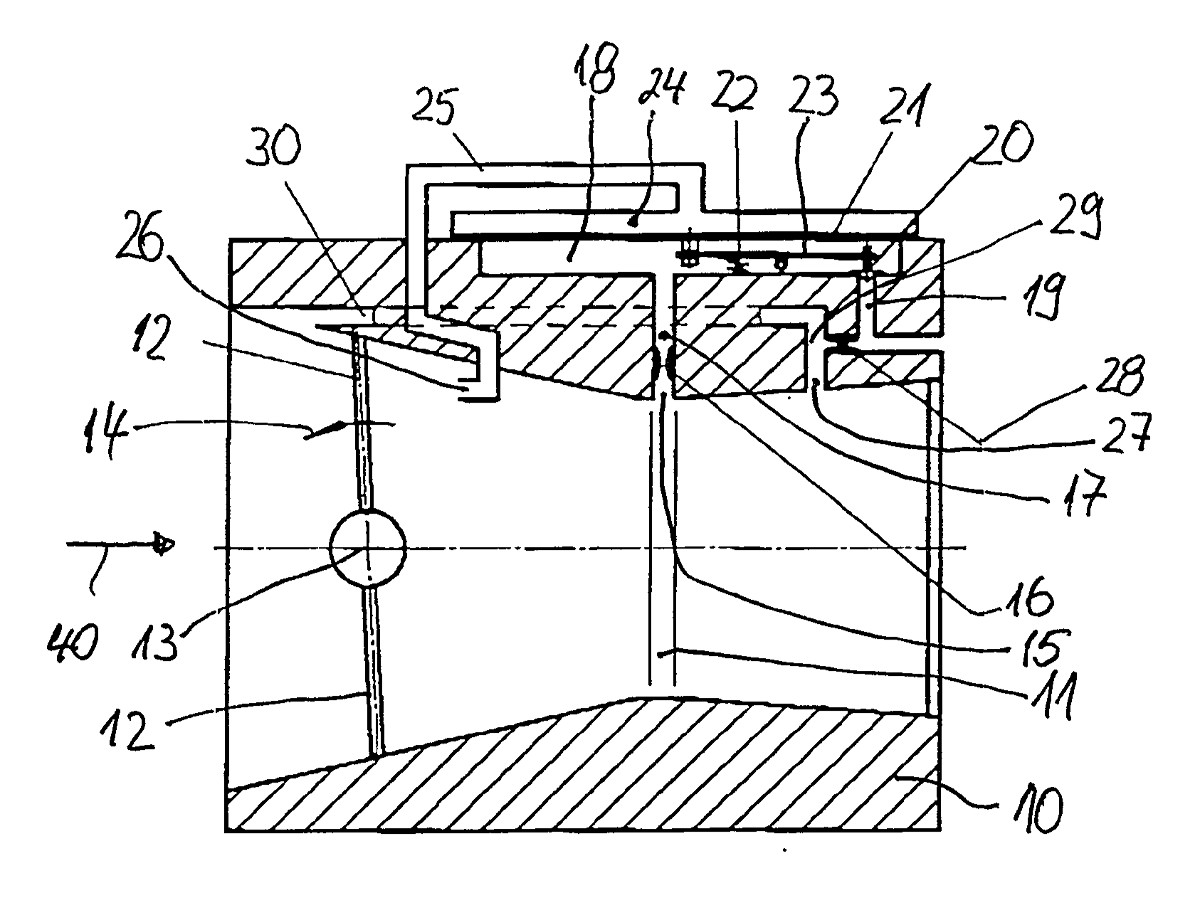

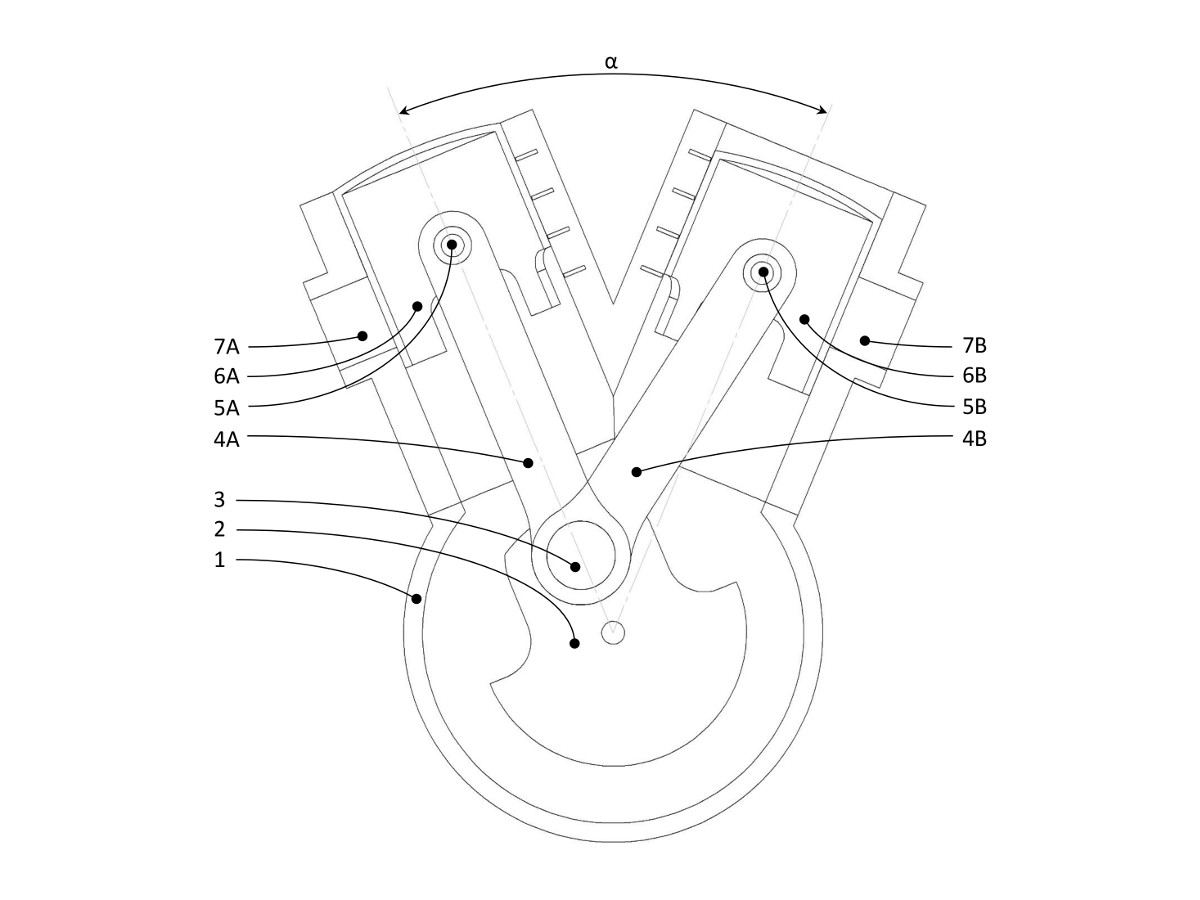

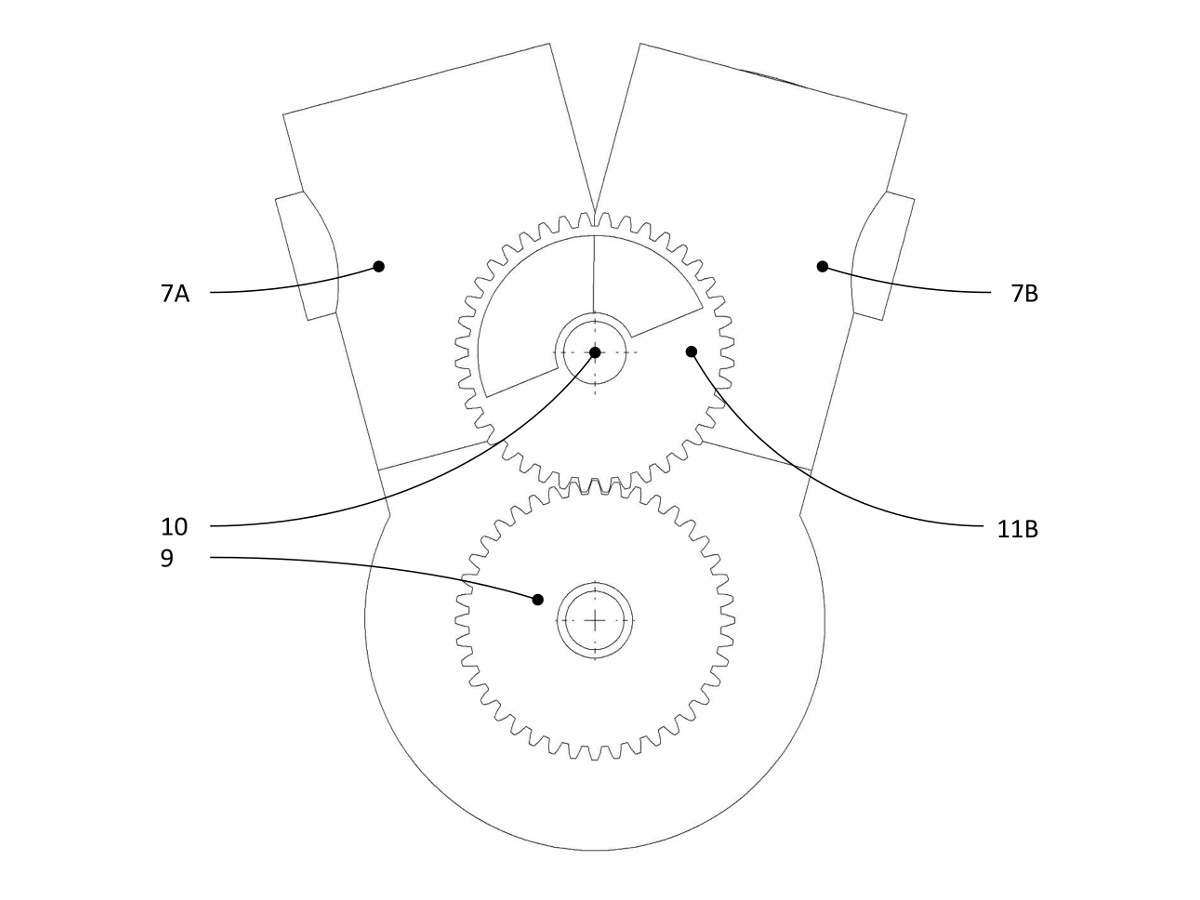

2-Cylinder 2-Stroke Engine

Rotary engines are simply the best. But the effort of making them does not depend much on the engine capacity as part count and processes required are the same, and their weight advantage is only noticeable from a certain engine size. So below a power of approx. 10kW it gets increasingly difficult to compete against 2-stroke engines that can use fairly simple, mass-produced components.

Current aviation 2-stroke engines are often either single-cylinder engines or twin-cylinder boxer engines that ignite once per revolution. As a result these engines produce a short power peak that puts high stress on the engine components and reduces the output efficiency. To overcome this, multi-cylinder engines have been proposed, but such engines require separated crankcases or an external charger, which makes them more complex and heavy.

A good alternative to this would be a V-arrangement of cylinders that distributes the peak load over a wider crank angle. Such an arrangement profits from the low volume changes around dead centres, so it does not need separated crankcases and can be designed very simple and light. Also the frontal area is small, and a balancing shaft can be placed in between the cylinders to achieve lower vibration and to have the output in the middle of the engine.

The engine is only a concept with a patent applied for so far, and we are too busy with other things to take it further. But we are happy to license the concept to anyone interested.